Clinker to Clay: Unlocking the Potential of More Sustainable Cement

Cement plays a crucial role in the construction industry, providing the foundation for countless infrastructure projects worldwide. However, the production of traditional cement comes with significant environmental challenges. One of the key components of cement, known as white clinker, is responsible for a substantial carbon footprint. In recent years, there has been a growing focus on developing alternative solutions that can reduce the environmental impact of cement production. In this blog post, we explore the concept of transforming white clinker to clay, a promising pathway towards more sustainable cement.

Understanding White Clinker:

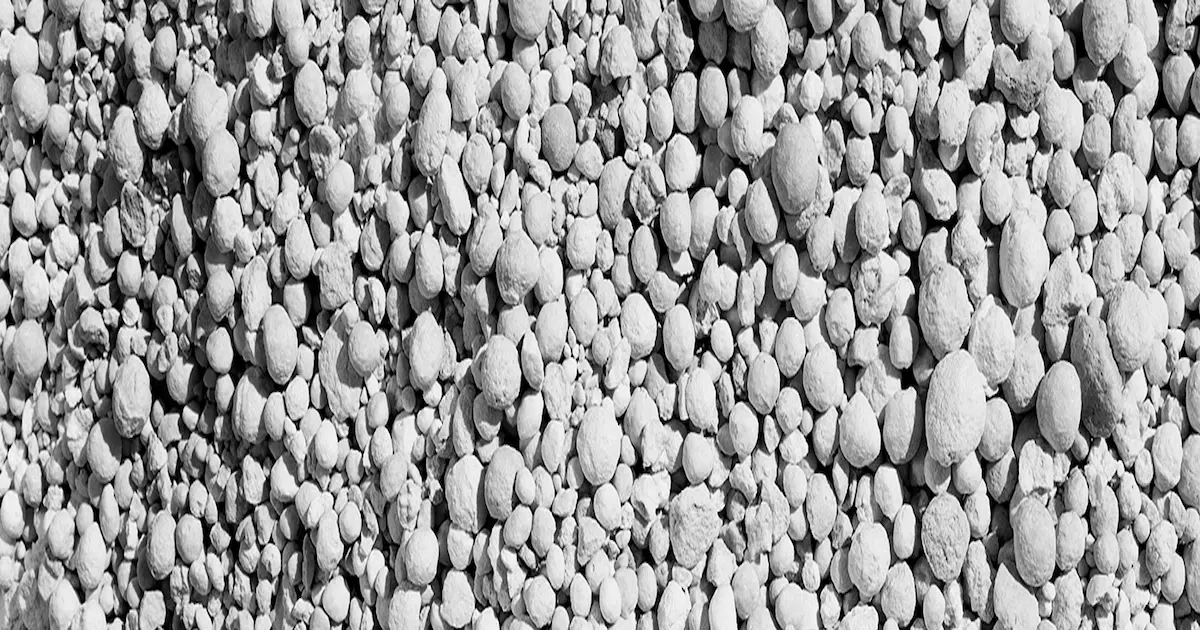

Clinker is a nodular material used as the main ingredient in the production of cement. It is formed by heating a mixture of limestone, clay, and other additives at high temperatures in a kiln. The resulting clinker is then finely ground to produce white cement. However, the production of clinker is an energy-intensive process that emits a significant amount of carbon dioxide (CO2) into the atmosphere, making it a major contributor to greenhouse gas emissions.

The Environmental Impact of Traditional Clinker:

The traditional production of clinker involves the combustion of fossil fuels, such as coal, to provide the necessary heat for the kiln. This process not only releases CO2 but also contributes to air pollution and resource depletion. Additionally, the extraction of raw materials for clinker production can lead to habitat destruction and land degradation.

White Clinker: An Alternative Approach:

A white clinker is a specialized form of clinker that offers a potential solution to some of the environmental challenges associated with traditional clinker production. Unlike conventional clinker, white clinker is produced using a different raw material composition, typically incorporating a higher proportion of clay. This alternative formulation results in lower CO2 emissions during the manufacturing process.

Clinker Tiles: A Sustainable Building Material:

Clinker tiles are an innovative application of white clinker that showcases its potential as a sustainable building material. These tiles are manufactured using white clinker and can be used for various purposes, including flooring, wall coverings, and decorative elements. Clinker tiles offer durability, aesthetic appeal, and improved thermal properties, making them an excellent choice for eco-conscious architects and builders.

Clinker Manufacturers in UAE: Pioneering Sustainability:

The United Arab Emirates (UAE) has emerged as a leading hub for clinker production, with numerous manufacturers in the region. These manufacturers are at the forefront of sustainability initiatives, investing in research and development to explore alternative approaches to clinker production. By leveraging the potential of white clinker and other sustainable practices, they are contributing to the transformation of the cement industry.

White Clinker Price in UAE: Balancing Cost and Sustainability:

The cost of clinker in the UAE is influenced by various factors, including raw material availability, production efficiency, and market demand. While sustainable alternatives may initially entail slightly higher costs, the long-term environmental benefits, and potential savings through reduced energy consumption and CO2 emissions make them a worthwhile investment.

Clinker Suppliers in UAE: Facilitating Sustainability:

To support the adoption of more sustainable cement solutions, several clinker suppliers in the UAE are offering a wide range of products and services. These suppliers understand the importance of sustainable development and actively collaborate with stakeholders across the construction industry to promote the use of environmentally friendly materials.

Conclusion:

The transition from clinker to clay represents a significant step towards achieving more sustainable cement production. By embracing white clinker and exploring alternative materials and manufacturing processes, the industry can reduce its environmental impact, mitigate CO2 emissions, and contribute to a greener future. As the UAE continues to lead the way in clinker production and innovation, it sets a promising example for other regions.